WELDING

Contour is a specialized supplier of welded assemblies from sheet metal. All processing steps, including the production of the welding components, are coordinated to be able to weld efficiently and accurately.

We deliver both specialized sheet metal in small series, as well as volume parts where the welding activities are carried out by our welding robot.

WELDING SUPPLIER

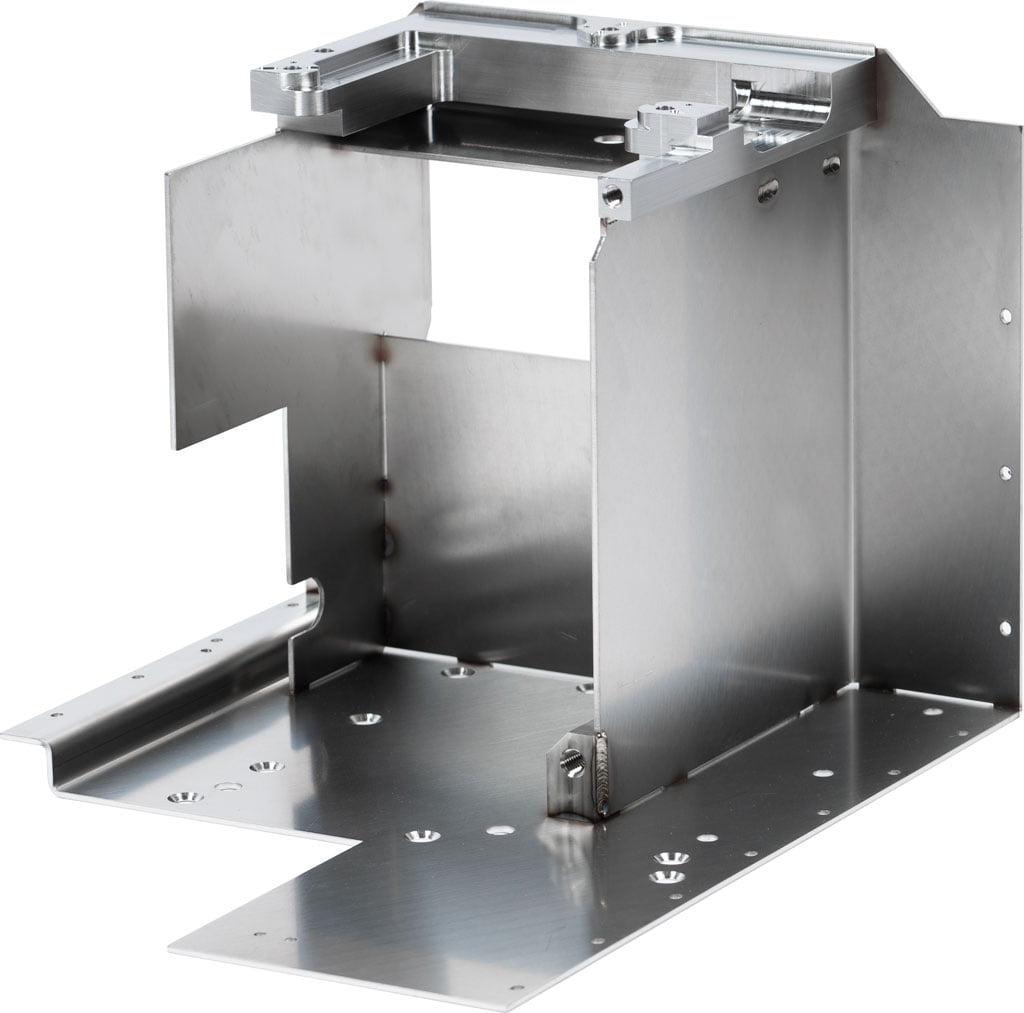

Where tolerance build-up and flatness are important criteria, Contour is your suitable supplier. For our customers, we weld complex welded assemblies with an accuracy of tenths of millimeters.

Assemblies can consist of a combination of bent sheet metal, turned and milled parts, laser-cut tubes, and various purchased parts. Our experienced employees have the knowledge to (re)construct a design in such a way that an accurate and reproducible end product can be realized.

Our experience with assembly is appreciated by customers in various sectors. We are often involved at an early stage in the design phase.

STAINLESS STEEL WELDING

WELD ROBOT

TIG WELDING

WELDING

GRINDING AND FINISHING

We distinguish ourselves with the high-quality finish we can achieve with our welded assemblies. Our team is able to grind the weld seams, even on curved surfaces, to the desired radius. The grinding direction can then be applied as desired.

Products with our stainless steel finishing are used, among other things, at check-ins in various airports, metro access gates in Paris, and in the housings of medical equipment.

STAINLESS STEEL WELDING & FINISHING

Contour has the knowledge and experience in-house to give products the desired appearance after stainless steel welding. Contact us to discuss the possibilities.

WELDING TRAINING

Our employees have completed various internationally recognized welding training programs. Our team includes visual welding inspectors (VT-w-1 and VT-w-2) who can assess welds according to NEN-EN-ISO 5817 and EN-ISO 10042. We also count an international welding engineer (IWE) among our colleagues.

We combine practical experience with theoretical knowledge to serve our customers as effectively as possible with welded assemblies.

CERTIFIED WELDING

In certified welding, a representative from an independent institute demonstrates that we can weld a specific product in accordance with the indicated standards. Under supervision, a test product is welded. The weld is then visually inspected and tested in accordance with the standard specifications. In the event of a successful result, a welding procedure qualification is issued for the welded assembly.

We apply certified welding when our customers request it. For example, when a weld is particularly critical, or the welded assembly must comply with specific regulations.

GRINDING

FINISHING

TIG WELDING

TUBE FRAME

SMART WELDING FACTORY

We are a participating member of the Fieldlab Smart Welding Factory. The aim of Smart Welding Factory is to keep technical knowledge in the Netherlands up to date and thereby strengthen our competitive position compared to other countries.

The emphasis is on cost-effective production of single-piece welded assemblies. This is achieved by automating production steps where technological developments in welding technology enable us to combine automation with flexibility.

RIDE REACT-EU PROJECT

In the Ride project, Contour works together with various project partners to carry out preliminary research and feasibility studies on new production techniques for welded assemblies. The goal is to accelerate innovation and thus increase production capacity and reduce production costs. Want to know more? Read the press release.

TIG WELDING TORCH

WELD ROBOT

STAINLESS STEEL WELDING JIG

THIN SHEET METAL

QUALITY STANDARD

Contour has developed a standard in which the level of finish of the weld seam and finishing of a welded assembly is defined. Based on samples and practical examples, our technicians can discuss with customers what requirements a product must meet. It is clear to all involved what quality level is requested. This way, we control both the quality and cost price of our welded assemblies.

APPOINTMENT

Curious about the possibilities? Then contact our sales team to schedule an appointment.

FRAME CONSTRUCTION

WELDING

GRINDING

FINISHING

SERIES PRODUCTION

In series production, we make the most efficient use of our welding robot and smart welding jigs. When quantities increase, we invest in reducing cycle times and devise the optimal division between tack welding and final welding for a welded assembly. In this way, we reduce the cost per product as far as possible.

PARTNER

Our technicians stay in contact with our customers’ technicians, keeping lines short. Together we continue to look for improvements in design and production method.

As a sheet metal specialist we support our customers in optimally dividing products into sheet metal parts. The result is an efficiently reproducible welded assembly.