METALWORKING

Within metalworking, we specialize in several disciplines. Contour’s strength lies in the combination of all metalworking processes that we can carry out in-house. We master each process in a high-quality, guaranteed, and professional way.

We work as much as possible with CNC-controlled machines. These machines enable us to produce with high precision. By saving NC programs and applying revision management, we can reuse and, if necessary, improve the NC program for every production series of a product. In this way, we deliver consistently high quality with short lead times.

Because we carry out a wide range of metalworking processes in-house, we can optimally coordinate the different successive metalworking steps with each other, both technically and logistically. In this way, we work cost-efficiently and keep lead times short.

By combining both technical knowledge and good business processes, we create added value for our customers.

SHEET METAL WORKING

Sheet metal working is a category of metalworking that focuses on working with metal sheet. Contour specializes in sheet metal working of thin sheet. This is our core business. Our customers have been coming to us for years for the high-quality sheet metal we provide, whether it’s challenging and specialized components or larger series of fully automated produced products.

ASSEMBLY

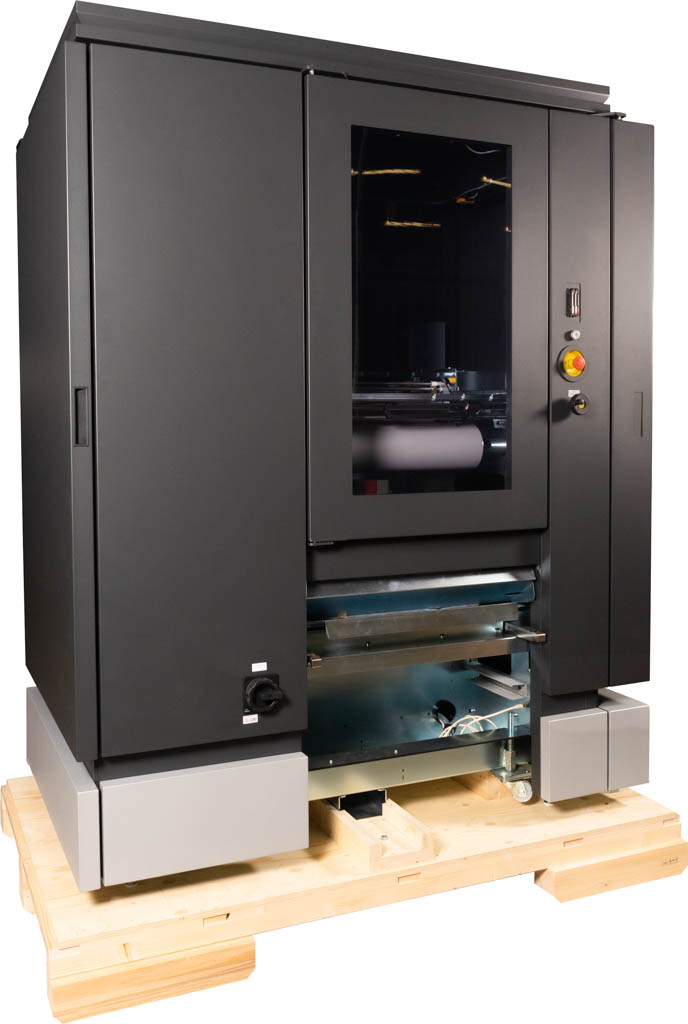

Ultimately, all welded assemblies, sheet metal parts, and purchased parts come together in the assembly department at the right time. Here, they are then assembled into a final product and provided with suitable packaging.

In the assembly department at Contour, we work with flexibly arranged assembly zones. We can quickly set up and dismantle each zone, tailored to the products being assembled at that moment.

The department can see on dashboards for which production orders the required parts from the bill of materials are already available for assembly. With the press of a button, the parts can be called from the warehouse and prepared in the assembly department for assembly.