Sheet metal working

Sheet metal working is the collective name for various ways of processing sheet metal. Examples of sheet metal operations are laser cutting, bending, and welding. At Contour, we have practically all types of sheet metal working in-house.

Where possible, we use fully CNC-controlled machines. Some of these CNC machines are also equipped for fully automatic production. Our factory never stands still.

All types of sheet metal working

As a supplier of sheet metal working, we consider it important to be able to provide our customers with cost-effective solutions. That is why we carry out practically all possible operations in-house. A combination of our own powder coating installation, cleanroom, and pickling line makes us unique in the Netherlands. Because we perform all sheet metal operations in-house, we keep costs low, quality high, and lead times short.

Click on a sheet metal operation for more info about the production process.

SHEET METAL WORKING

SHEET METAL WORKING

Sheet metal working as core business

Sheet metal working is our core business. In the 1950s we started with sheet metal working, and in the 1980s we installed one of the first industrial laser cutting machines for sheet metal in the Netherlands. Since then, we have gradually expanded the number of sheet metal operations we perform in-house.

We now supply sheet metal products to customers in different sectors, in both low- and high-tech market segments.

SHEET METAL WORKING

SHEET METAL WORKING

Tailor-made sheet metal working

As a supplier of sheet metal working, we respond to our customers’ needs for technology, logistics, and quality. The approach we propose varies depending on the request.

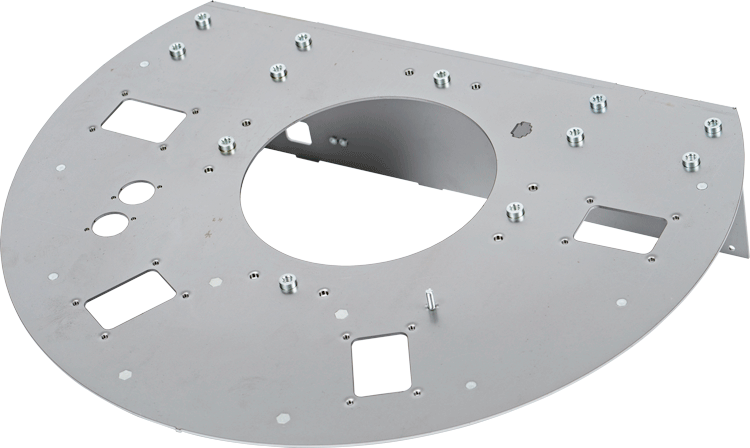

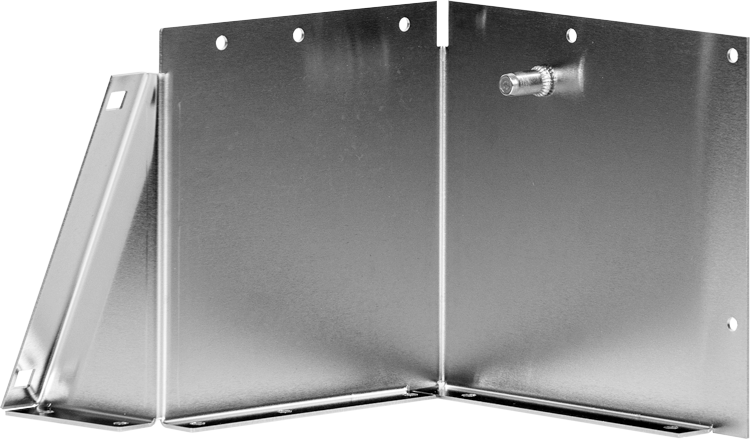

Some projects are well-suited for autonomous and fully automatic sheet metal working, like the single-piece products shown in the photo to the right. These products are manufactured in large quantities and shipped to the customer in full trailer loads. Production runs via fully automated machines, where the focus is mainly on logistics and automation. Communications with the customer primarily revolve around logistical aspects.

By contrast, very specialized sheet metal working of complex assemblies in small quantities calls for craftsmanship and manufacturability. The challenge now lies in the technical feasibility and any post-processing of the finished product.

We have our own powder coating installation, which enables us to guarantee consistent product quality and short lead times for sheet metal products.