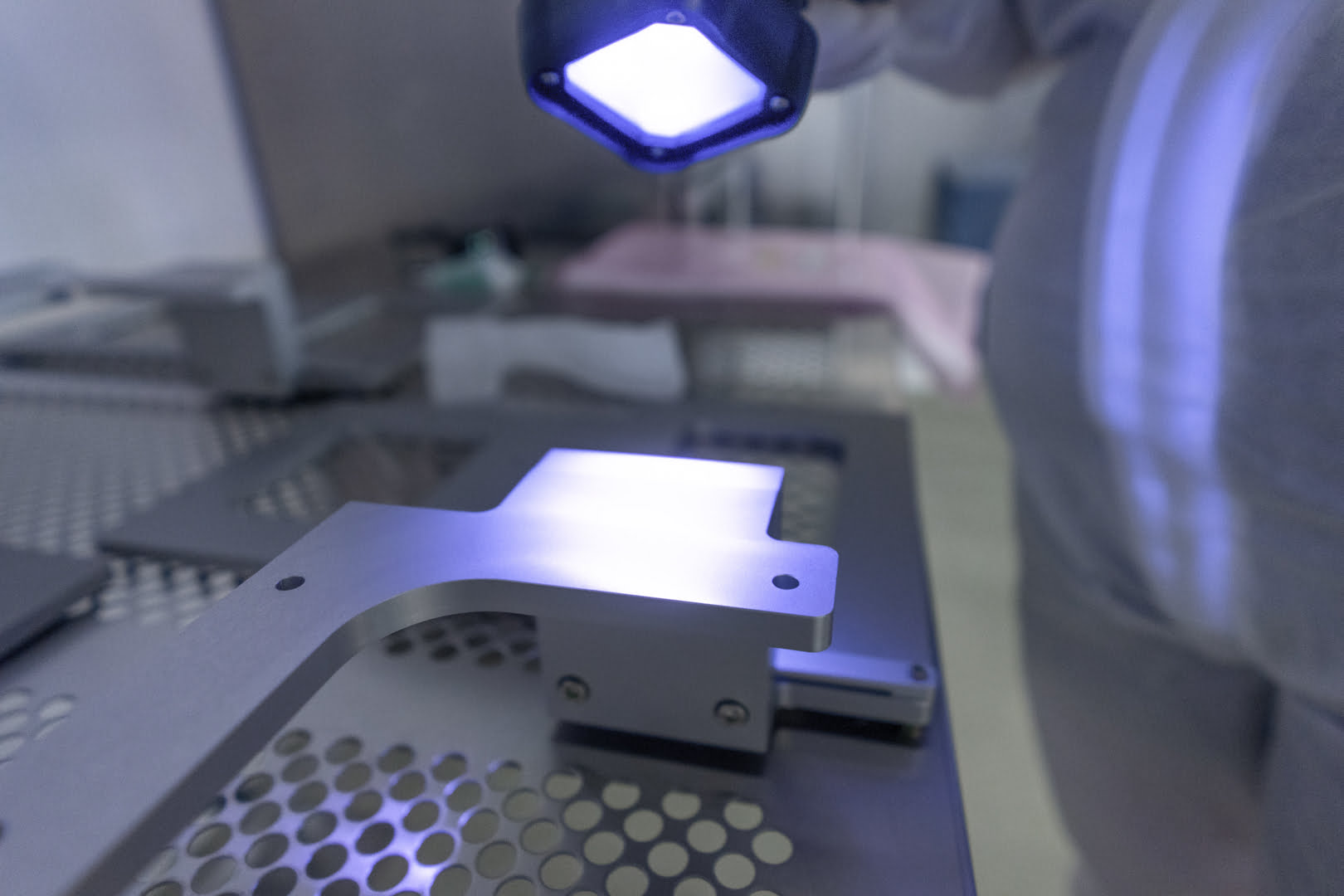

CLEANROOM ASSEMBLY

Contour is a supplier of cleanroom-cleaned products. In our cleanroom, we can clean, sheet metal, and welded components, and also assemble and package purchased parts.

The cleanroom is mainly used for customers in the medical and semiconductor industries. The installation meets the guidelines as established in the ISO 14644-1 class 5 cleanroom classification.

Because we have an in-house cleanroom, the sheet metal products we produce do not need to be transported to external suppliers. This reduces the chance of damage during transport. It also shortens the lead time and improves our ability to ensure compliance with strict assembly instructions.

We have our own pickling and passivation installation. For analyses such as TOC and RGA testing, we work closely with leading service providers in the Netherlands. We manage our supply chain in both technical and logistical areas.

CLEANROOM

PACKAGING

CLEANROOM

CLEANING

COMPLEX CLEANROOM ASSEMBLY

Where regular providers of cleanroom activities primarily focus on cleaning, at Contour the assembly of complex assemblies is one of the core activities. The cleanroom is therefore part of the assembly department. The employees are experienced in assembling products for various sectors including the semiconductor industry.

PROCESBORGING

If desired, we can perform the assembly based on step-by-step work instructions with checklists. In the cleanroom, we use mobile tablets to make this possible.

CLEANROOM

UV CONTROL

CLEANROOM

LAYOUT